Step Flashing is a type of flashing used where a sloped roof meets a vertical wall, such as chimneys or along the sides of dormers. It’s installed in “steps” along the roofline, with each piece tucked under a shingle and bent up against the wall or chimney.

Flashing around the base of the chimney usually includes step flashing and counter flashing, working together to prevent water from penetrating your roof decking.

The proper way to install chimney flashing is to grind out a channel in the brick and/or stone; the copper or aluminum flashing should run up 4 to 8 inches on all four sides of the chimney. Chimney flashing is a vital component of any roofing system and is a critical safeguard against water intrusion and long-term damage.

Counter/Wall Flashing is a protective layer of flashing installed over another piece of flashing to help seal and waterproof areas where a roof meets a vertical surface, such as a chimney or wall.

Its main purpose is to cover and protect the top edge of the base flashing, preventing water from seeping behind it.

Counter flashing is often embedded into masonry joints or attached to the wall surface and overlaps the base flashing below, allowing water to shed away from the structure.

This flashing is important in areas exposed to heavy rain or snow, providing an added barrier for water intrusion.

Valley Flashing is a critical component of a pitched roof system and is installed at the areas where the two roof slopes meet.

There are two types of valley flashings used: the first type is known as an open valley; this is where a piece of aluminum or copper is laid along the valley and left visible with shingles trimmed on each side stopping short of the center.

The type of open valley we recommend is a “W” valley since it has a raised ridge going down the center forming a “W” shape; this helps guide water away from both roof planes along separate paths.

The second type is a closed valley; this is where the shingles from both sides of the slope extend across the valley and meet in the middle covering the flashing underneath. In areas with heavy rain or snow, open valleys are often preferred due to their durability and water-shedding performance.

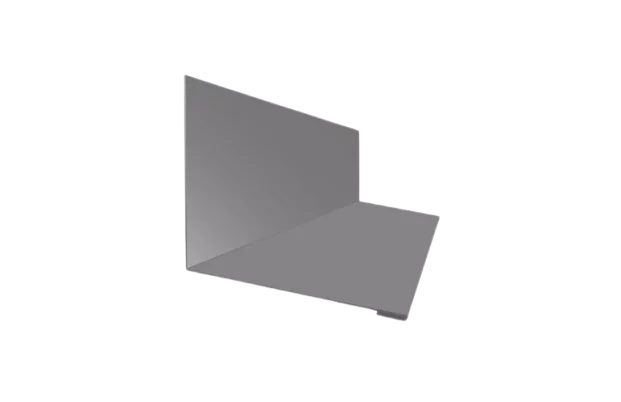

Surface Mount Flashing is used to protect the transition between a vertical wall and a roofing surface.

Surface mount flashing is an additional layer of flashing that’s often seen on surfaces such as brick, stucco, and siding. The top edge of the flashing is sealed with a waterproof sealant to prevent water from getting behind it.

Surface mount flashing bridges the gap between the roof and wall, preventing leaks and water damage.

Ridge Capping serves as the protective covering placed along the peak where two roof slopes meet.

Its main purpose is to seal the ridge line against water intrusion and wind uplift, ensuring the roof’s highest point remains secure and watertight. While many homeowners default to using asphalt shingles for ridge capping, copper and aluminum are also viable options.

These metals are durable, long-lasting, and will most definitely enhance your home’s curb appeal.

By considering materials beyond standard shingles, homeowners can significantly improve the longevity and performance of their roofing system.

Drip Edges are a metal flashing installed along the edges of a roof (typically at the eaves and rakes), playing a vital role in directing water away from the roof structure and into the gutters.

The drip edge is installed beneath the first layer of shingles and extends slightly past the roof’s edge with a small angled lip at the bottom. This lip is designed to break the surface tension of water, causing it to drip clear of the fascia board and roof decking, rather than running back underneath the shingles or behind the gutters.

Without a drip edge, water can work its way into the roof edge and lead to rotting the fascia board, mold growth, and damaging the roof deck. Drip edges also provide support for shingles at the perimeter of the roof, helping them resist wind uplift and improving the roof’s overall wind resistance.

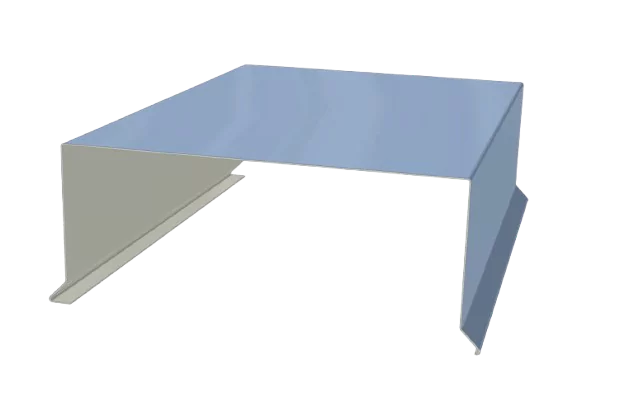

Coping/Parapet Capping is a protective covering installed on top of parapet walls to prevent water from entering the wall system.

This form of capping is commonly used on flat and low-slope roofs with parapet walls typically seen on commercial buildings, shopping centers, schools, warehouses, and residential homes.

The top of the parapet is extremely vulnerable to water infiltration so it’s imperative that the proper materials are used to protect the integrity of the wall. The most common materials used to cap a parapet wall are aluminum and copper.

Quick Links

Service Areas

Services

Contact

LICENSED & INSURED:

2126882-DCWP

WC-38805-H25